Optical fiber holders

FH-60-250 fiber holder

для использования в аппаратах Fujikura 80S, 19S, 80S+, 19S+, 62S, 62S+, 22S, 12S, а также скалывателях CT-30, CT-06.

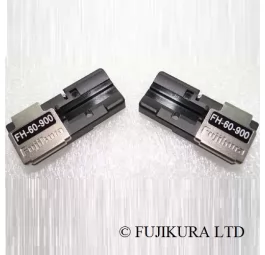

FH-60-900 fiber holder

для использования в аппаратах Fujikura 80S, 19S, 80S+, 19S+, 62S, 62S+, 22S, 12S, а также скалывателях CT-30, CT-06.

FH-60-DC250 fiber holder

для использования в аппаратах Fujikura 86S, 46S, 80S, 19S, 80S+, 19S+, 62S, 62S+, 36S, 22S, 12S, а также скалывателях CT50, CT08, CT-30, CT-06.

FH-60-LT900 fiber holder

для использования в аппаратах Fujikura 86S, 46S, 80S, 19S, 80S+, 19S+, 62S, 62S+, 36S, 22S, 12S, а также скалывателях CT50, CT08, CT-30, CT-06.

FH-FC-20 fiber holder

для использования в аппаратах Fujikura 86S, 46S, 80S, 19S, 80S+, 19S+, 62S, 62S+, 36S, 22S, 12S, а также скалывателях CT50, CT08, CT-30, CT-06.

FH-FC-30 fiber holder

для использования в аппаратах Fujikura 86S, 46S, 80S, 19S, 80S+, 19S+, 62S, 62S+, 36S, 22S, 12S, а также скалывателях CT50, CT08, CT-30, CT-06.

AD-10 fiber plate

для оптического волокна в покрытии 250 мкм для получения скола длиной 5-20 мм в скалывателях Fujikura CT-30.

AD-30B fiber plate

для получения скола длиной 16 мм в скалывателях Fujikura CT-30 и CT-06.

AD-30С fiber plate

для оптического волокна в патчкордах и дроп-кабелях в скалывателях

AD-50 fiber plate

для оптического волокна в покрытии 250 мкм и более для получения скола длиной 5-20 или 10-20 мм

FH-70-900 fiber holder

для использования в аппаратах Fujikura 86S, 46S, 80S, 19S, 80S+, 19S+, 62S, 62S+, 36S, а также скалывателях CT50, CT08.

An integral component of any optical network, however, like copper, are detachable connectors, connection plates, holders, clamps and other accessories.

Most manufacturers of FOCL welding machines offer special holders as an accessory or in the basic set of the welder, in which a connector is placed instead of one of the fibers. To prepare the splicer for mounting the connector, it is enough to remove one of the fiber holders, usually fixed with one screw, and replace the connector holder.

At the moment, glue connectors are practically not installed by users on their own due to the complexity of the technology and the low quality of the result. They are mainly installed by manufacturers of patch cords and pigtails. At the same time, these companies have polishing machines, which also increases the speed of installation. And the quality of polishing will be noticeably better than doing it by hand.

Fast connectors (Fast Connector) - it is recommended to use it as a temporary solution during repair and restoration work, if there is no “at hand” welding machine, or if it is impossible to use it. Subsequently, such connectors must be replaced with more reliable and durable solutions.

Fiber termination with pigtails is the most common method. Pigtails provide excellent optical performance and reliability. It is justified to use them when installing large optical crosses installed in the operator's / provider's premises. But for installation in outdoor junction boxes and for terminating fiber-optic communication lines in the subscriber's premises - pigtails are not very suitable due to poor resistance to mechanical stress and dimensions.

Splice On connectors are still inferior to pigtails in popularity. However, even in spite of the higher cost, their use is already justified for the installation of outdoor junction boxes and cable termination at the subscriber's premises when deploying FTTx and PON. This is due to the excellent optical characteristics, protection from mechanical damage and climatic influences, durability, as well as simplicity and fairly high installation speed. Most likely, with a decrease in cost and an increase in consumption, this technology can completely replace all others. And along with all manufacturers of patch cords, because having a welding machine, Splice On connectors and a patch cord, any user can make a high-quality patch cord in a few minutes.